EPOXY RESIN DRYING & CATALYSIS ELECTROMAGNETIC WAVE OVENS

Resin lines, and in general production plants of slabs, need:

-

An appropriate design

Optimize the flow of slabs

Use the proper materials

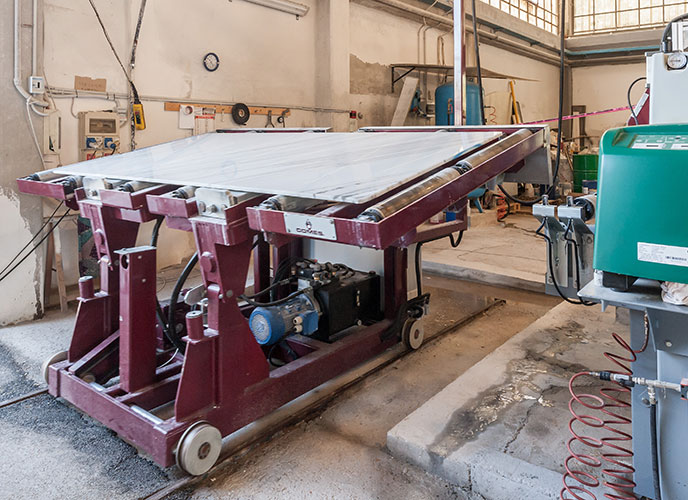

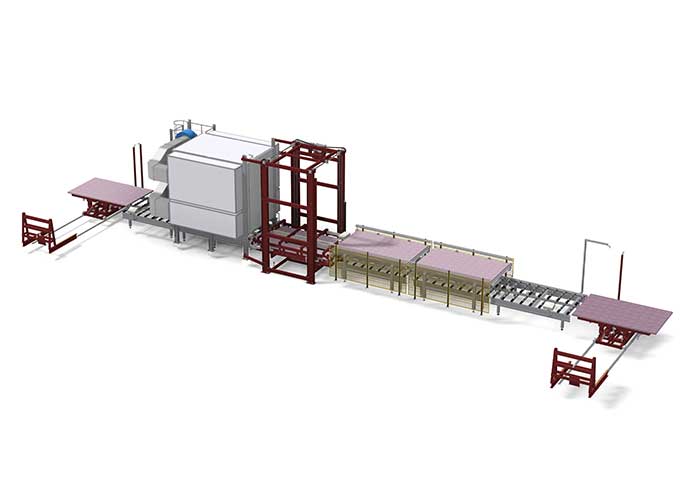

In COMES we know what we are talking about…every resin line is customized according to the type of material processed, the production required, the type of resin needed and the area available in the plant

We use the Xilex ovens ARES 3500 and KRONOS 3500 that allow us to design resin lines and marble and granite production plants with 4 in 1 versatility:

-

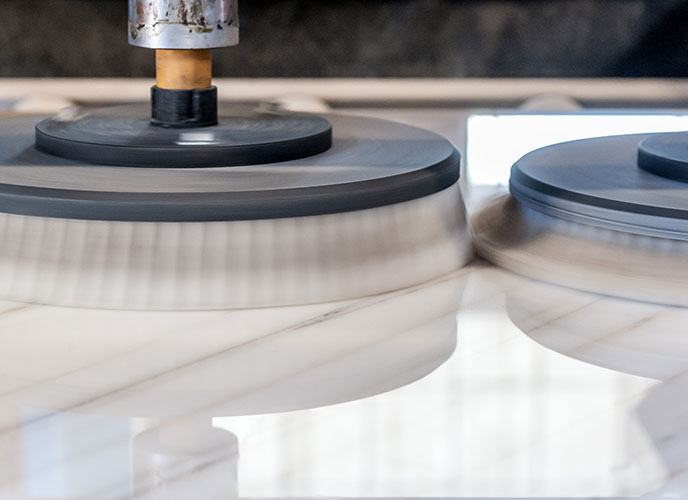

Improving the quality of the finish of the materials

prolonging the brightness

reducing processing times and costs

increasing production

With the support of Xilex, the provider of advanced radiation systems!

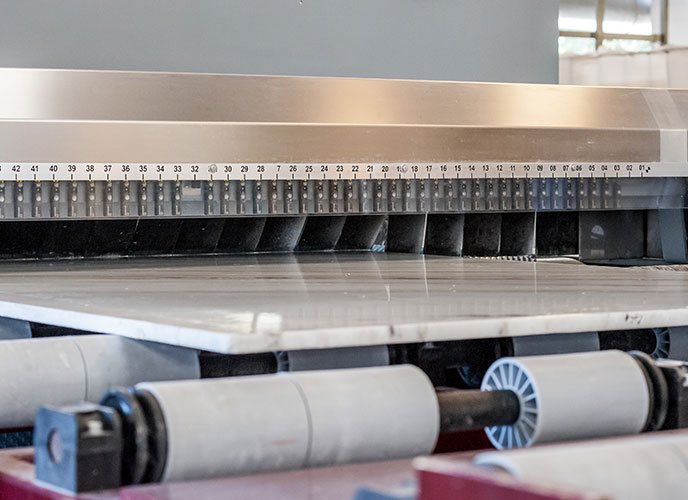

ARES 3500 DRY TECHNOLOGY

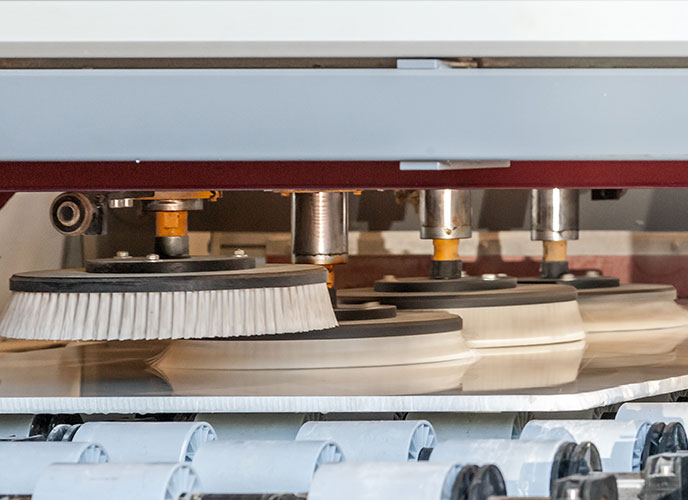

The use of the ARES 3500 technology allows to dry water 100% and to help later filter properly the resin without the use of vacuum, filling all cracks and holes to make the best adhesion

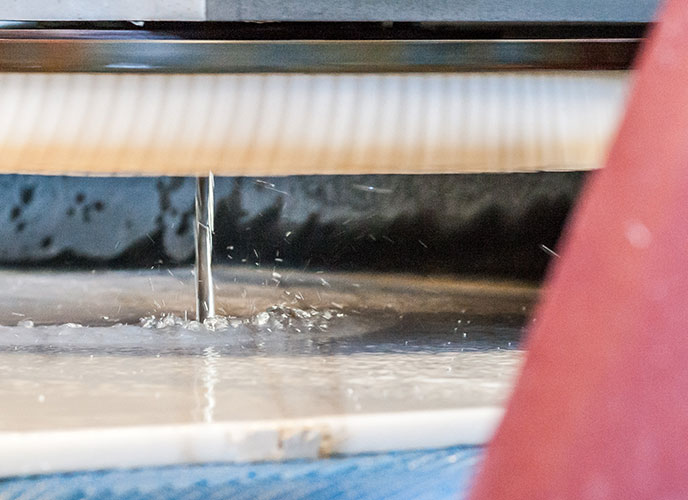

KRONOS 3500 HARDENING TECHNOLOGY

The use of the KRONOS 3500 technology produces a “molecular vibration” that accelerates the activation of the resin hardening. This technology, working together with an accumulator studied for this purpose, allows, with the lower cost of energy, to achieve greater filtration, penetration, and affects (light, medium, dark tones, etc.) in marble and granite. It allows to eliminate waiting times of slabs of 24-48-72 hours as it is processed, it can be polished immediately

COST

-

Lower energy consumption (machine doesn’t consume when it doesn’t produce

Lower resin consumption (molecular vibration allows optimal filtration of the resin)

Less processing space (NO intermediate warehouses)

Low maintenance

Low cost / m2

FEATURES

-

Better filtering of the resin. (does not need vacuum)

Higher resistance and brightness duration

Less breaks

Less amount of resin adapting to the desired effects (Light, dark tones, etc.)

Less curing time

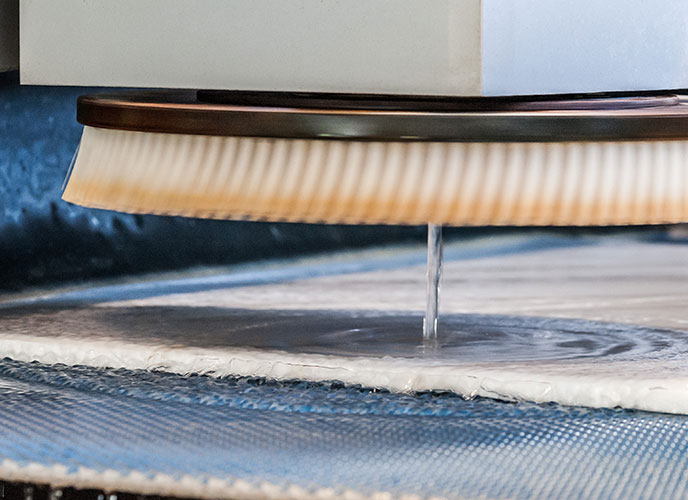

Less overall processing time (allows to work IN LINE with the polisher) IN LINE PLANT CONCEPT

Less handling time

Possibility of diversity of finishes

Reduced dimension > less space occupation

Immediate operations (without preheating)

No intermediate warehouses > IN LINE process (at the end of the line the resin is fully catalysed, which allows working IN LINE with the polisher and avoid unnecessary material transport and storage)

DON’T use MW > is not dangerous for operators

Guaranteed production although the weather condition vary

Radiation + chemical: allows the best finishes after polishing

System allows the evolution to water-based resin, more ecological than current ones

Speed can be adjusted to the required production

No major foundation work are required