EPOXY RESIN DRYING & CATALYSIS ELECTROMAGNETIC WAVE OVENS

Resin lines, and in general production plants of slabs, need:

-

An appropriate design

Optimize the flow of slabs

Use the proper materials

In COMES we know what we are talking about…every resin line is customized according to the type of material processed, the production required, the type of resin needed and the area available in the plant

We use the Xilex ovens ARES 3500 and KRONOS 3500 that allow us to design resin lines and marble and granite production plants with 4 in 1 versatility:

-

Improving the quality of the finish of the materials

prolonging the brightness

reducing processing times and costs

increasing production

With the support of Xilex, the provider of advanced radiation systems!

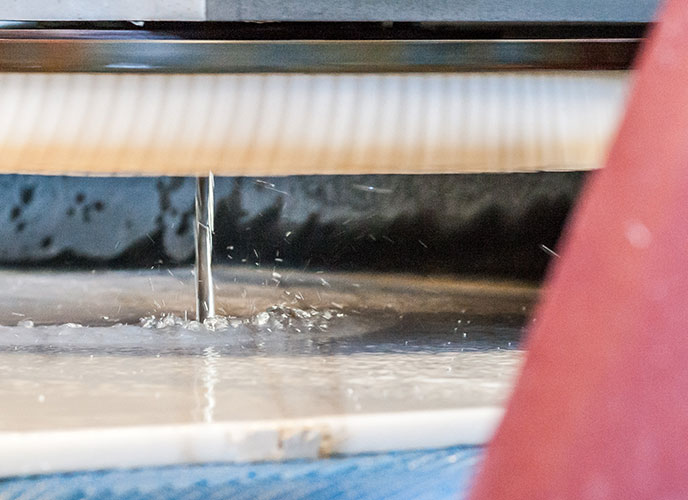

ARES 3500 DRY TECHNOLOGY

The use of the ARES 3500 technology allows to dry water 100% and to help later filter properly the resin without the use of vacuum, filling all cracks and holes to make the best adhesion

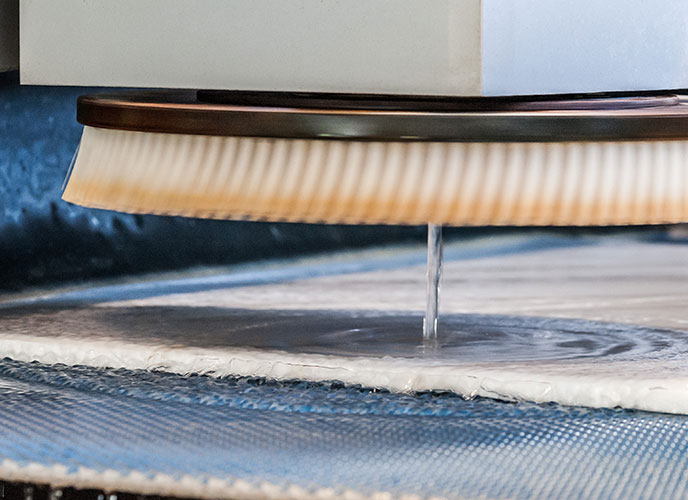

KRONOS 3500 HARDENING TECHNOLOGY

The use of the KRONOS 3500 technology produces a “molecular vibration” that accelerates the activation of the resin hardening. This technology, working together with an accumulator studied for this purpose, allows, with the lower cost of energy, to achieve greater filtration, penetration, and affects (light, medium, dark tones, etc.) in marble and granite. It allows to eliminate waiting times of slabs of 24-48-72 hours as it is processed, it can be polished immediately

COST

-

Lower energy consumption (machine doesn’t consume when it doesn’t produce

Lower resin consumption (molecular vibration allows optimal filtration of the resin)

Less processing space (NO intermediate warehouses)

Low maintenance

Low cost / m2

FEATURES

-

Better filtering of the resin. (does not need vacuum)

Higher resistance and brightness duration

Less breaks

Less amount of resin adapting to the desired effects (Light, dark tones, etc.)

Less curing time

Less overall processing time (allows to work IN LINE with the polisher) IN LINE PLANT CONCEPT

Less handling time

Possibility of diversity of finishes

Reduced dimension > less space occupation

Immediate operations (without preheating)

No intermediate warehouses > IN LINE process (at the end of the line the resin is fully catalysed, which allows working IN LINE with the polisher and avoid unnecessary material transport and storage)

DON’T use MW > is not dangerous for operators

Guaranteed production although the weather condition vary

Radiation + chemical: allows the best finishes after polishing

System allows the evolution to water-based resin, more ecological than current ones

Speed can be adjusted to the required production

No major foundation work are required

Download Pdf

COMESCAN

NEWS & EVENTS

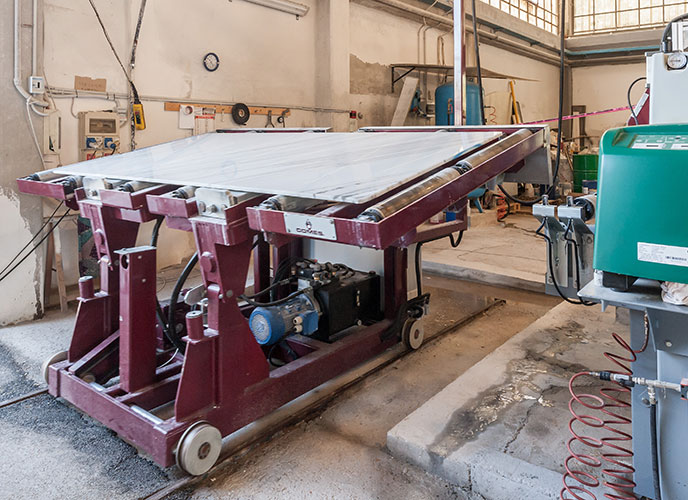

LOADING & UNLOADING AUTOMATIONS

One of the key components of reinforcement lines is the handling system, which must let the material move from one processing step to the next, quickly and safely. In some of CO.ME.S.’s plants specifically designed to treat extremely fragile slabs, the material is placed on the trays, gently taken through the entire process, and eventually ejected.

Download Pdf

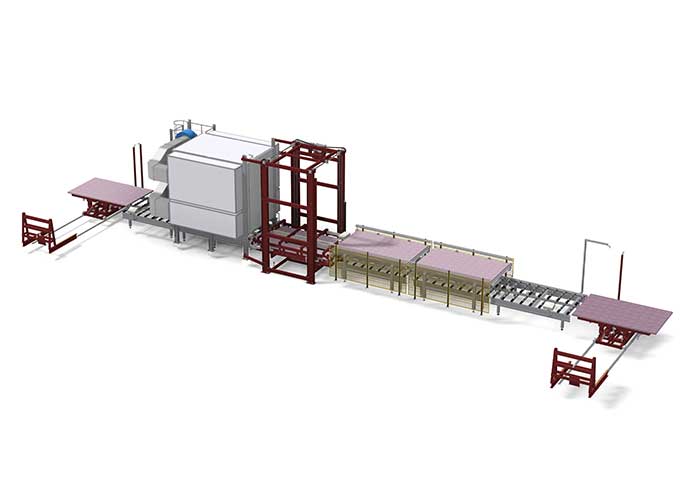

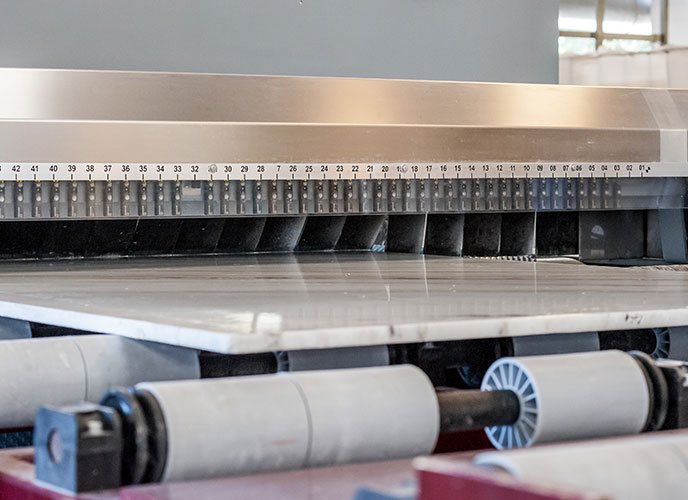

RESIN FILLING LINES

Such equipment has been designed to soak stone slabs (mainly marble and granite slabs) with chemical resins to improve their mechanical strength and/or appearance through an entirely automatic process. The process may be summed up in these steps: feeding in the slab, priming the slab, coating the slab surface with a layer of liquid resin where needed, stacking the slab away until the resin has set, and taking the slab out.

Download Pdf

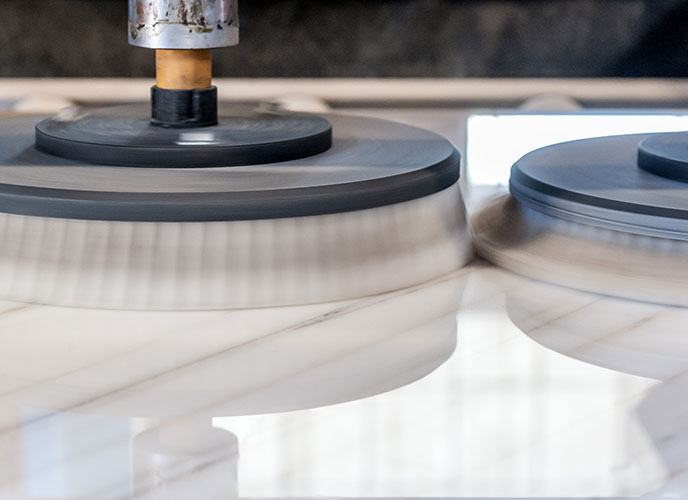

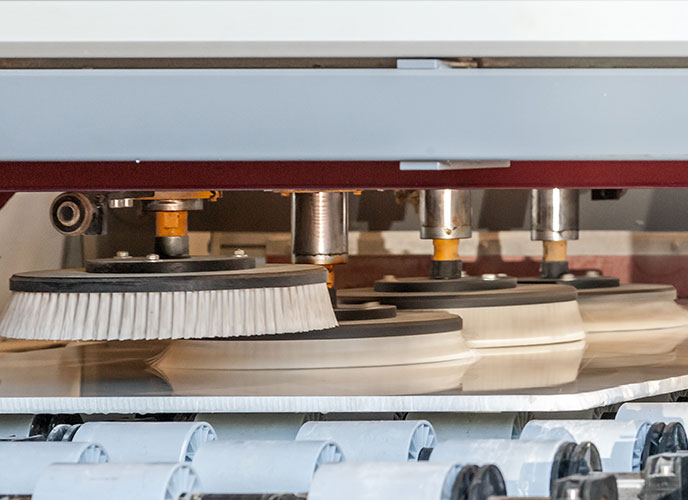

CO.ME.S. POLISHING MACHINES

The “STORM” polishing machine by CO.ME.S. is the result of the company’s 40 years of experience in manufacturing polishing heads for marble, granite and ceramic.

Design, ergonomics, performance and safety are the principles that inspire our work, so we can provide every buyer with the well-known quality of CO.ME.S.s products. Every single detail of the machine has been designed with unparalleled care.

Countless hours of design and factory tests have gone into the STORM polishing line until it met CO.ME.S. strictest standards.

Download Pdf

HTS Polishing Head

Polishing/Calibratin heads with multipurpose attachment for all kinds and models of multi-head and single-head polishing machines.

They are bought not only by end users but by lots of machine manufacturers all over the world as well.

The main advantages of these heads are:

1) The internal design has much fewer parts than the old heads. Its system (international patent for COMES’ Storm) for driving the swinging arm, using a differently-sloping cogged gear (instead of cams), avoids any clearance that could prevent the arms swinging evenly and consistently in both directions (as opposed to cam-based systems); such accuracy also prevents consumables (diamonds and abrasives) wearing out unevenly, thereby saving money and delivering excellent polishing results.

2) Easy, cheap maintenance. Fewer parts, a simple design and the fact that one half, if not actually just over one half, of them are commercial parts, so they can be found at any retailer or specialist shop all over the world, will save time and money (parts without a code next to the exploded view in the manual are commercial parts).

3) Flexibility and adaptability of the head, even on flawed surfaces once cut (for granite) or once baked (for ceramics) or specially corrugated (for ceramics, special engravings are provided in the moulds). This is because of the 12 heavy-duty steel ‘springs’ (see exploded view, part no. 69) that make the head extremely flexible as well as equally effective and powerful on surfaces that need to be gauged or polished.

4) All mechanical parts are lubricated by just one type of lubricant. They use either grease type 00 or oil, as shown in the list we provide or as written on a table on the head.

STORM 5 Polishing Head

Polishing/Calibrating head with multipurpose attachment for all kinds and models of multi-head and single-head polishing machines.

They are bought not only by end users but by lots of machine manufacturers all over the world as well.

The main advantages of these heads are:

1) The internal design has much fewer parts than the old heads. Its system (international patent for COMES’ Storm) for driving the swinging arm, using a differently-sloping cogged gear (instead of cams), avoids any clearance that could prevent the arms swinging evenly and consistently in both directions (as opposed to cam-based systems); such accuracy also prevents consumables (diamonds and abrasives) wearing out unevenly, thereby saving money and delivering excellent polishing results.

2) Easy, cheap maintenance. Fewer parts, a simple design and the fact that one half, if not actually just over one half, of them are commercial parts, so they can be found at any retailer or specialist shop all over the world, will save time and money (parts without a code next to the exploded view in the manual are commercial parts).

3) Flexibility and adaptability of the head, even on flawed surfaces once cut (for granite) or once baked (for ceramics) or specially corrugated (for ceramics, special engravings are provided in the moulds). This is because of the 12 heavy-duty steel ‘springs’ (see exploded view, part no. 69) that make the head extremely flexible as well as equally effective and powerful on surfaces that need to be gauged or polished.

4) All mechanical parts are lubricated by just one type of lubricant. They use either grease type 00 or oil, as shown in the list we provide or as written on a table on the head.

STORM 3 Polishing Head

Polishing/Calibrating head with multipurpose attachment for all kinds and models of multi-head and single-head polishing machines.

They are bought not only by end users but by lots of machine manufacturers all over the world as well.

The main advantages of these heads are:

1) The internal design has much fewer parts than the old heads. Its system (international patent for COMES’ Storm) for driving the swinging arm, using a differently-sloping cogged gear (instead of cams), avoids any clearance that could prevent the arms swinging evenly and consistently in both directions (as opposed to cam-based systems); such accuracy also prevents consumables (diamonds and abrasives) wearing out unevenly, thereby saving money and delivering excellent polishing results.

2) Easy, cheap maintenance. Fewer parts, a simple design and the fact that one half, if not actually just over one half, of them are commercial parts, so they can be found at any retailer or specialist shop all over the world, will save time and money (parts without a code next to the exploded view in the manual are commercial parts).

3) Flexibility and adaptability of the head, even on flawed surfaces once cut (for granite) or once baked (for ceramics) or specially corrugated (for ceramics, special engravings are provided in the moulds). This is because of the 12 heavy-duty steel ‘springs’ (see exploded view, part no. 69) that make the head extremely flexible as well as equally effective and powerful on surfaces that need to be gauged or polished.

4) All mechanical parts are lubricated by just one type of lubricant. They use either grease type 00 or oil, as shown in the list we provide or as written on a table on the head.

DAMP Calibrating Head

The DAMP is a special satellite head with 5 or 6 abrasive tools used to hone/lap even tiles of different size. It consists of a revolving casing in spheroid graphite cast iron, equipped with 5 or 6 grindstones which are secured to special corrosion-proof rests. The internal gears, bearings and all other mechanisms are soaked in an oil bath, with long-life, heat-proof seals. The motor drive provides the working force. The fixed flange must only withhold the torque reaction, without having to be rigidly fastened to the machine body. distinctive feature of these heads is the special internal vibration damper system that polishes the tile evenly, even when the surface is particularly bent. In addition, the shafts can be angled away from the axis of rotation of the head, to make it easier for the abrasive grindstone to remove and finish the material during the process. The head should be installed on honing machines provided with a backpressure feature.

Technical specifications of the DAMP

Number of satellites No. 5/6

Max power kW 15

Min head revolving speed revs/min. 400

Max head revolving speed revs/min. 600

Abrasive grindstone max diam. mm 150

Amount of lubricant l 9.3/9.2

Weight with lubricant Kg 100/102

Max honing diameter mm 460